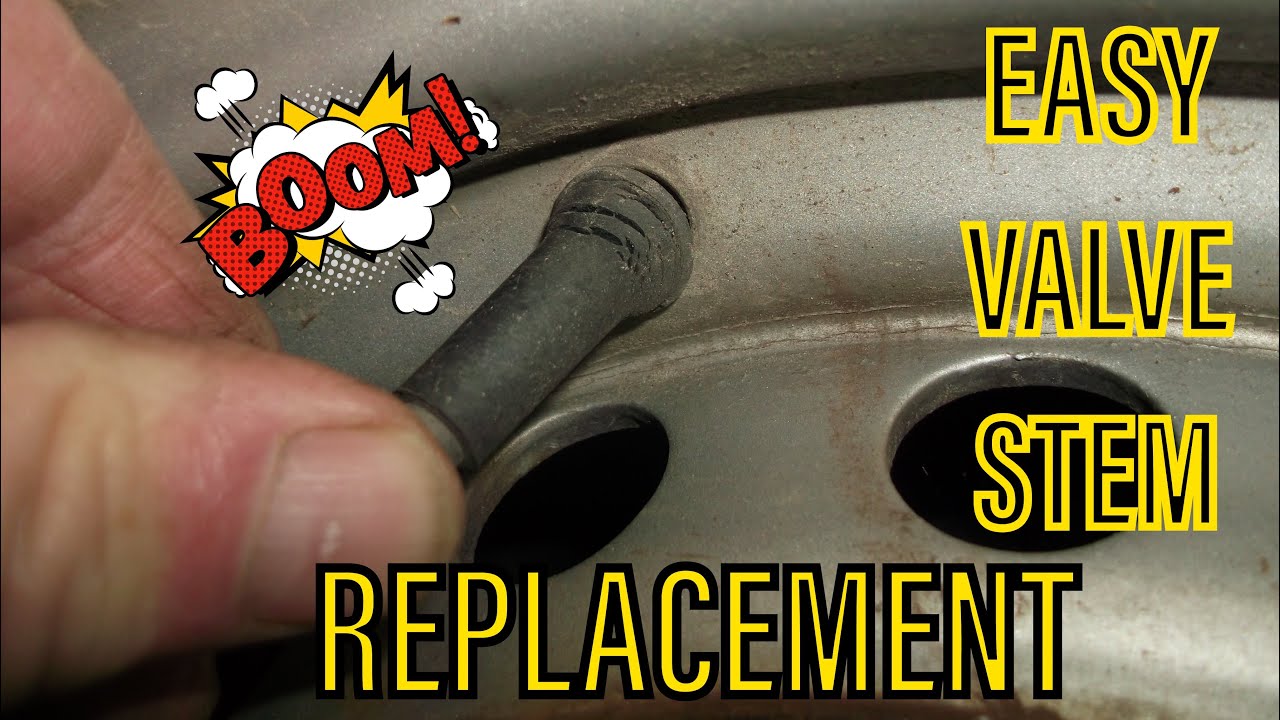

How Long Does It Take to Replace a Valve Stem

Replacing a valve stem typically takes between 30 minutes to an hour. It depends on the tire type and the technician’s skill level.

Valve stem replacement is a crucial repair for maintaining tire integrity and vehicle safety. The valve stem is the tiny protrusion from your tire that you unscrew when you need to inflate it. Over time, valve stems may deteriorate or become damaged, leading to air leaks and tire pressure issues.

Performing this task requires precision and the right tools, such as a valve stem tool, to ensure a proper fit and seal. Motorists should consider professional assistance as part of regular tire maintenance to avoid complications. Timely replacement of a valve stem preserves optimal tire function, contributes to fuel efficiency, and provides a smoother driving experience. Trusting a certified technician can save you time and prevent further tire-related concerns.

Valve Stem Basics

A valve stem plays a key role in tire health. This small component maintains proper tire pressure. Without it, your tire could deflate or fail. It is a tube made of metal or rubber. It sticks out from the tire rim. A cap on its end keeps out dirt and moisture. The cap also helps to maintain air pressure. At its core, the valve stem contains a spring-loaded valve. This valve opens to adjust air pressure or to add air. It’s a task that seems simple but is vital for tire performance.

Integral To Tire Health

- Maintains tire pressure: necessary for safety and efficiency.

- Avoids early tire wear: incorrect pressure causes uneven wear.

- Increases fuel economy: properly inflated tires are essential.

Signs Of Valve Stem Failure

| Sign | Explanation |

|---|---|

| Leakage | Air escapes, causing decreased pressure. |

| Cracking | Valve stem looks dry or cracked. |

| Difficulty Inflating | Air won’t go in when trying to inflate. |

Inspect the valve stem regularly. Look for signs of damage or wear. Check for hissing sounds. They indicate air might be escaping. A drop in tire pressure can also mean valve stem issues. Regular tire pressure checks are crucial. They ensure valve stems function as they should.

Credit: www.youtube.com

Preparation Steps

Before diving into the task of replacing a valve stem, proper preparation is crucial. This ensures a smooth and efficient process. It’s not just about having the right tools, but also ensuring safety throughout the procedure. Let’s explore what you need to prepare for this DIY automotive fix.

Tools And Materials Required

Gathering the right tools and materials is the first step. You will need:

- Valve stem tool – For removal and installation

- New valve stem – Match with your vehicle’s specifications

- Wrench set – To loosen and tighten parts

- Pliers – For pulling out the old stem

- Soap water solution – To check for air leaks post-installation

- Rubber mallet – Helps seat the valve stem

- Tire pressure gauge – To ensure proper inflation after replacement

Safety Measures

Personal safety is paramount. Here are the safety measures to follow:

- Wear gloves – Protects hands from debris and sharp objects

- Safety glasses – Shields eyes from dust and small particles

- Sturdy footwear – Prevents foot injuries

- Keep a first aid kit nearby – For any minor injuries during the process

- Work in a well-ventilated area – Ensures fresh air circulation

Be mindful of the vehicle’s stability. Use wheel chocks if necessary. Work on a flat surface. Keep distractions at bay for full focus on the task. These preparations pave the way for a successful valve stem replacement.

The Replacement Process

Valve stem replacement is a crucial repair for maintaining tire health. This process involves several steps. Each step must be performed with care. Proper execution ensures longevity and safety of your tires. Let’s explore each stage in detail.

Removing The Old Valve Stem

Removal of the old valve stem is the first step. The tire must be properly deflated before any work begins. Tire deflation prevents injuries and allows for safe removal. Mechanics use special tools called valve stem pullers for this task.

- Locate the valve stem on the tire.

- Use a valve core removal tool to take out the valve core and deflate the tire completely.

- Detach the tire from the wheel rim to reach the valve stem.

- Pull out the old valve stem from the rim hole.

Installing The New Valve Stem

The new valve stem must match your tire’s specifications. A mismatch can lead to tire damage. Mechanics often lubricate the new valve stem before installation. This makes the insertion smoother. The stem slides into the rim hole from the inside of the wheel.

- Select the correct valve stem size.

- Lubricate the new stem for easy insertion.

- Slide the stem through the rim hole from inside the wheel.

- Use a valve stem tool to pull the stem into place firmly.

Ensuring A Proper Seal

A good seal is vital to prevent air leaks. Once the new stem is in place, a mechanic will:

| Step | Detail |

|---|---|

| 1 | Check the fit: Ensure it sits flush against the rim. |

| 2 | Inspect for leaks: Apply soapy water around the stem and watch for bubbles. |

| 3 | Re-attach tire: Mount the tire back onto the wheel. |

| 4 | Refill the tire: Inflate the tire to the recommended pressure. |

| 5 | Final check: Do one last inspection for air leaks. |

With these steps complete, your tire will have a new, secure valve stem.

Time Considerations

When faced with the task of replacing a valve stem, understanding the duration of the process is crucial. The time it takes can vary, influenced by several factors. Knowing these time considerations ensures effective planning and less downtime. Optimal performance of your tires relies on the swift and proper execution of valve stem replacement.

Average Duration For Replacement

Typically, replacing a valve stem is a quick fix. An experienced mechanic should complete the task within 30 to 60 minutes. This assumes immediate availability of necessary tools and the new valve stem. Trust a professional for a swift resolution.

| Procedure Step | Estimated Time |

|---|---|

| Wheel Removal | 5-10 Minutes |

| Valve Stem Replacement | 15-30 Minutes |

| Wheel Reinstallation | 5-10 Minutes |

| Total Duration | 30-60 Minutes |

Factors That Impact Timing

Various elements can extend the valve stem replacement process. Each aspect should be considered to gauge timing accurately.

- Type of Vehicle: Some vehicles may require special attention or equipment.

- Valve Stem Type: Different types may need extra steps or care.

- Service Location: In-shop service typically proceeds more quickly than a roadside service.

- Technician Experience: Skilled technicians can resolve issues faster.

- Assess the vehicle and valve stem type.

- Ensure all tools and equipment are prepared.

- Book the service in advance to avoid waiting.

Prioritize these factors to enhance efficiency and minimize time spent on replacement.

Post-replacement Checklist

Once you’ve replaced a valve stem, a diligent post-replacement checklist ensures your safety and maintains vehicle performance. Follow these steps rigorously to ensure the job is done right. From checking for any leaks to taking your car for a test drive, each step is crucial in confirming the integrity of the replacement.

Checking For Leaks

After you’ve replaced a valve stem, checking for leaks is the first order of business. You want to ensure that no air is escaping from the new valve. Here’s how to check for leaks:

- Submerge the valve stem in soapy water.

- Look for bubbles that indicate escaping air.

- If bubbles form, re-examine the valve stem installation.

- Ensure the stem is tightened to the correct specification.

Test Drive Recommendations

To confidently determine that the valve stem replacement holds up, a test drive is essential. Observing the following test drive recommendations will help you assess the work:

- Drive for at least 10 minutes.

- Monitor the tire pressure indicator.

- Listen for any unusual sounds.

- Feel for any changes in the vehicle’s handling.

Address any issues with a professional mechanic if the tire pressure changes or handling seems off.

Credit: www.yourmechanic.com

Frequently Asked Questions On How Long Does It Take To Replace A Valve Stem

What Is A Valve Stem Replacement?

A valve stem replacement is a procedure to fix a damaged or leaking valve stem on a tire. It’s a small but crucial component that ensures tire pressure is maintained and air is not lost.

How Long Does It Take To Replace?

Replacing a valve stem typically takes about 30 minutes to an hour. The duration can vary based on the vehicle, tire type, and the technician’s experience.

What Tools Are Needed For Valve Stem Replacement?

Standard tools for this job include a valve stem tool, pliers, jack, and lug wrench. A tire machine is often used in professional settings for a faster replacement.

Can Driving On A Bad Valve Stem Cause Damage?

Driving on a bad valve stem can lead to tire damage and reduced vehicle handling. It’s important to replace it promptly to avoid dangerous situations on the road.

Conclusion

Replacing a valve stem is a relatively quick process, typically taking under an hour. Factors like experience and vehicle type can affect duration. Remember, proper tools and techniques ensure safety and efficiency. For DIY enthusiasts, a methodical approach guarantees a smooth operation.

Trust your vehicle’s integrity and get back on the road with confidence.