Can a Crankshaft Sensor Cause No Spark

Yes, a crankshaft sensor can cause no spark in an engine. A crankshaft sensor is a vital component in the ignition system of a vehicle.

It provides crucial information about the position and speed of the crankshaft, which is used by the engine control unit (ECU) to determine the timing of the spark for each cylinder. If the crankshaft sensor is faulty or malfunctions, the ECU may not receive the necessary input to initiate the spark, resulting in a no-spark condition.

This can lead to engine misfires, stalling, or complete engine failure. Therefore, a properly functioning crankshaft sensor is essential for the ignition system to work efficiently.

Credit: blazerforum.com

What Is A Crankshaft Sensor

A crankshaft sensor is a critical component in a vehicle’s ignition system, playing a key role in determining the position of the crankshaft and the speed at which it is rotating. This information is essential for precise fuel injection timing and accurate ignition system operation.

Function Of The Crankshaft Sensor

The crankshaft sensor, also known as the crank sensor, detects the position and rotational speed of the crankshaft. It sends this information to the engine control unit (ECU), which uses the data to control ignition timing and fuel injection. By accurately timing these processes, the crankshaft sensor ensures that the engine runs smoothly and efficiently.

Types Of Crankshaft Sensors

There are two main types of crankshaft sensors: magnetic and Hall effect sensors. Magnetic sensors use a magnet and a coil to generate electrical signals, while Hall effect sensors utilize a special semiconductor to produce voltage. Both types serve the same purpose but employ different methods to achieve accurate crankshaft position detection.

Symptoms Of A Faulty Crankshaft Sensor

The crankshaft sensor is a vital component in the engine’s ignition system. It plays a crucial role in providing the engine control unit (ECU) with data about the rotational speed and position of the crankshaft. A faulty crankshaft sensor can lead to a number of issues, causing the engine to misfire, stall, or experience difficulty in starting.

Engine Misfires

One of the primary symptoms of a faulty crankshaft sensor is engine misfires. This occurs when the sensor fails to accurately detect the position of the crankshaft, resulting in incorrect timing of the spark plug. As a result, the spark plugs may fire at the wrong time or not at all, leading to misfires.

Engine misfires can cause a range of problems such as poor fuel efficiency, reduced power, and increased emissions. If you notice your engine running rough, sputtering, or experiencing a loss of performance, it could be due to a faulty crankshaft sensor.

Stalling Or Difficulty In Starting The Engine

Another common symptom of a faulty crankshaft sensor is stalling or difficulty in starting the engine. The sensor’s role in providing the ECU with accurate crankshaft position data is essential for ignition timing. When the sensor fails, the ECU may not receive the necessary information to properly ignite the fuel mixture, resulting in stalling or difficulty starting the engine.

If you experience repeated instances of stalling or find it hard to start your vehicle, a malfunctioning crankshaft sensor may be the culprit.

It is important to address any issues related to a faulty crankshaft sensor promptly. Ignoring these symptoms can lead to further damage to your vehicle’s engine and other components, resulting in costly repairs. If you notice any of these symptoms, it is recommended to have a professional mechanic diagnose and replace the faulty crankshaft sensor to ensure the proper functioning of your engine.

Can A Faulty Crankshaft Sensor Cause No Spark

A faulty crankshaft sensor can indeed cause a lack of spark in an ignition system. The crankshaft sensor, part of the engine’s electronic control system, plays a crucial role in determining the timing of spark generation in the combustion chambers. When this sensor malfunctions, it can prevent the generation of spark, leading to poor engine performance or even a complete engine failure.

The Role Of The Crankshaft Sensor In Spark Generation

The crankshaft sensor is responsible for detecting the position and rotational speed of the crankshaft, which helps the engine control unit (ECU) calculate the precise timing of spark release in each cylinder. As the crankshaft rotates, the sensor detects its position and relays the information to the ECU. Based on this data, the ECU determines the exact moment to generate an electrical spark through the ignition coil, igniting the air-fuel mixture in the combustion chamber.

How A Faulty Crankshaft Sensor Can Prevent Spark

When the crankshaft sensor becomes faulty, it can render the ECU unable to accurately detect the position and speed of the crankshaft. This can disrupt the timing of spark generation, resulting in a lack of spark in the combustion chambers. Without a spark, the air-fuel mixture cannot ignite, causing the engine to misfire or fail to start.

A faulty crankshaft sensor can exhibit various symptoms, such as intermittent loss of power, engine stalling, or failure to start. Additionally, the engine’s electronic control system may detect this problem and trigger a diagnostic trouble code (DTC) to identify the issue.

It’s important to diagnose and replace a faulty crankshaft sensor promptly to restore proper spark generation and ensure the smooth operation of your vehicle. Regular maintenance and periodic inspection of the crankshaft sensor can help prevent such issues and keep your engine running smoothly.

Diagnosing And Testing A Crankshaft Sensor

Diagnosing and testing a crankshaft sensor is crucial in determining if it is causing a no spark issue. The crankshaft sensor is responsible for detecting the position and speed of the crankshaft, and if it malfunctions, it can result in a lack of spark in the ignition system. Here are some methods to diagnose and test a crankshaft sensor.

Using A Multimeter

To diagnose a faulty crankshaft sensor, the first step involves using a multimeter to measure the sensor’s electrical resistance. Before testing, ensure the sensor is disconnected from the vehicle’s electrical system to prevent any damage to the multimeter or the vehicle’s electrical circuitry. Use the multimeter to measure the resistance of the sensor’s terminals and compare the readings with the manufacturer’s specifications to determine if the sensor is within the acceptable range.

Checking For Proper Signal

To further test the crankshaft sensor, it’s essential to check for the proper signal output. This can be done by connecting the multimeter to the sensor’s terminals and observing the voltage readings while cranking the engine. A functioning sensor should produce a fluctuating voltage signal as the engine rotates, indicating that the sensor is accurately detecting the crankshaft’s position and speed. If the sensor fails to produce the expected signal, it may be defective and require replacement.

Replacing A Faulty Crankshaft Sensor

A faulty crankshaft sensor is a common cause of engine misfires and a no spark condition in modern vehicles. If your car is experiencing these issues, it might be time to replace the crankshaft sensor. In this guide, we will walk you through the step-by-step procedure of replacing a faulty crankshaft sensor, along with the tools required for the job.

Tools Required

Before you begin the replacement process, you will need the following tools:

- Socket wrench set

- Socket extension

- Flathead screwdriver

- New crankshaft sensor

- Torque wrench

- Clean cloth or rag

Step-by-step Replacement Procedure

Follow these steps to replace a faulty crankshaft sensor:

- Step 1: Disconnect the negative terminal of the car battery to ensure safety.

- Step 2: Locate the crankshaft sensor on your vehicle. It is typically located near the engine’s crankshaft pulley or on the transmission housing.

- Step 3: Remove any components that obstruct access to the crankshaft sensor using the appropriate tools. This may include removing the air intake duct, electrical connectors, or other parts.

- Step 4: Once the sensor is exposed, use your socket wrench and socket extension to remove the bolts or screws that secure the sensor in place.

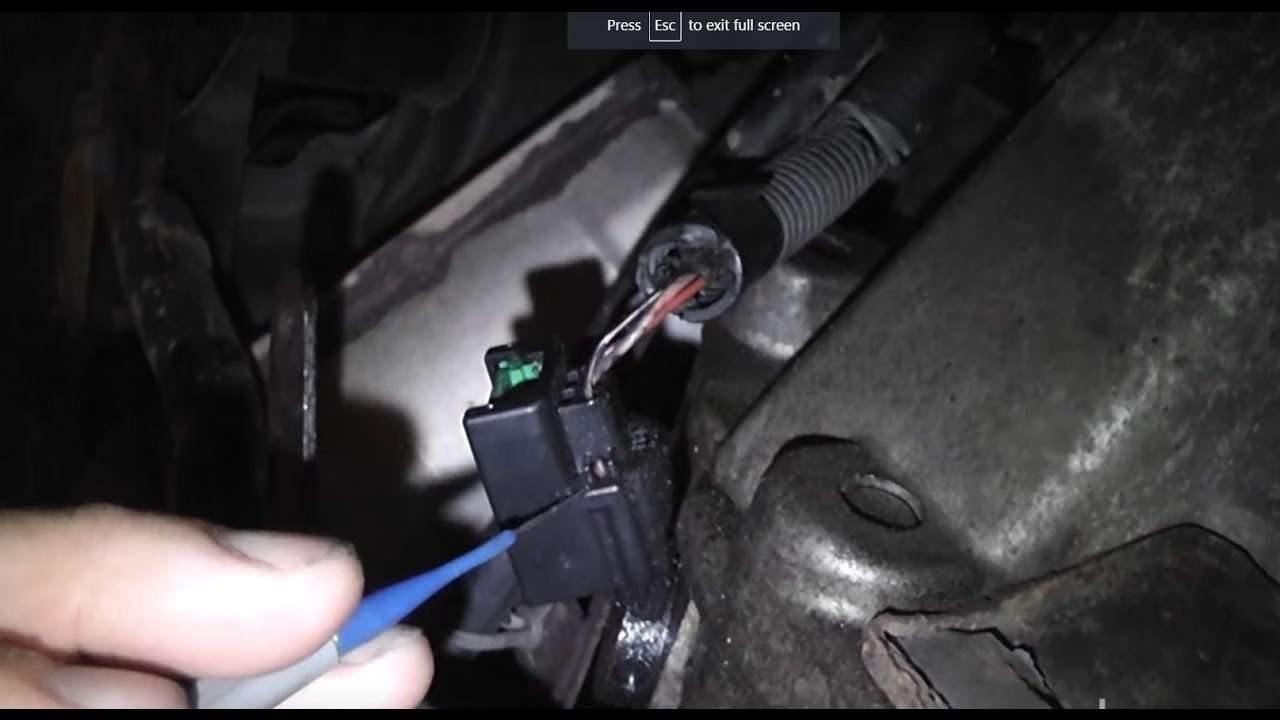

- Step 5: Gently disconnect the electrical connector on the crankshaft sensor by carefully prying it off with a flathead screwdriver.

- Step 6: Take your new crankshaft sensor and align it with the mounting hole. Make sure it is properly seated before tightening the bolts or screws.

- Step 7: Use a torque wrench to tighten the bolts or screws to the manufacturer’s specifications. This will ensure that the sensor is securely fastened.

- Step 8: Reconnect the electrical connector to the new crankshaft sensor and reassemble any components that were removed earlier.

- Step 9: Finally, reconnect the negative terminal of the car battery and start the engine to test the new crankshaft sensor’s functionality.

By following these steps, you can easily replace a faulty crankshaft sensor and resolve potential issues with engine misfires and a no spark condition. Remember to consult your vehicle’s manual for any specific instructions or torque specifications that may vary depending on the make and model.

Credit: www.aa1car.com

Credit: m.youtube.com

Frequently Asked Questions On Can A Crankshaft Sensor Cause No Spark

Can A Faulty Crankshaft Sensor Cause No Spark In The Engine?

Yes, a faulty crankshaft sensor can cause no spark in the engine. The crankshaft sensor is responsible for measuring the position and speed of the crankshaft. If it fails, the engine’s computer won’t receive the necessary information to ignite the spark plugs, resulting in a lack of spark and the engine not starting.

It is an essential component for proper combustion.

Conclusion

The crankshaft sensor can indeed cause a lack of spark in your vehicle’s ignition system. It is an essential component that helps in the proper functioning of the engine. So, if you are experiencing issues with no spark, consider checking the crankshaft sensor to ensure smooth engine performance.

Trusting in the functionality of this vital component can help in resolving potential issues with spark ignition. Understanding the importance of the crankshaft sensor can be pivotal in enhancing the overall efficiency and performance of your vehicle.