Can a Crankshaft Sensor Cause a Car Not to Start

Yes, a faulty crankshaft sensor can prevent a car from starting. It is essential for engine operation.

Starting a car may become an unexpected challenge if the crankshaft sensor malfunctions. This sensor plays a vital role in engine management, as it monitors the position and rotational speed of the crankshaft. The engine control unit (ECU) relies on data from the crankshaft sensor to adjust the fuel injection and spark timing.

Without accurate input from this sensor, the ECU cannot make the precise adjustments necessary for an engine to start and run smoothly. A car with a defective crankshaft sensor typically exhibits symptoms such as poor acceleration, engine misfires, and decreased fuel economy. Diagnosing and fixing a faulty crankshaft sensor is crucial for the restoration of proper engine function and preventing starting issues.

Symptoms Of A Faulty Crankshaft Sensor

A car’s crankshaft sensor plays a critical role in the engine’s functioning. It ensures the engine’s timing is precise for both fuel injection and ignition. When it fails, the symptoms can be easy to notice yet crippling to the vehicle’s operation. Let’s dive into the signs indicating a faulty crankshaft sensor that could leave you stranded.

Intermittent Stalling

Unexpected engine stalling is a telltale sign.

Your car may stall without warning, posing a risk especially if it happens while driving. A defective crankshaft sensor can lead to erratic signals that confuse the engine’s computer.

- Sudden engine stop while at a red light

- Stalling during slow traffic movements

- Car fails to restart immediately after stalling

Ignition Trouble

Starting the car becomes a gamble. With a faulty sensor, the engine may crank but not start.

| Symptom | Possible Experience |

|---|---|

| No-start condition | Turn the key, engine cranks, no start |

| Long cranking | Engine takes longer than usual to start |

| Irregular firing | Engine misfires during startup |

These ignition issues suggest that the engine lacks proper timing due to sensor failure.

Role Of The Crankshaft Sensor In Engine Operation

The crankshaft sensor plays a pivotal role in the heart of your car’s engine. It’s a crucial component that ensures your engine operates efficiently. Without it functioning properly, your car might not even start.

Monitoring Engine Speed

The crankshaft sensor keeps real-time tabs on your engine’s speed, detailed in revolutions per minute (RPM). It sends this data directly to your car’s computer. The computer uses this input to make critical engine control decisions. If the sensor fails, the computer lacks essential information, leading to starting issues.

Timing Fuel Injection And Ignition

Proper fuel injection and ignition timing are paramount for an engine’s startup and performance. The crankshaft sensor ensures that fuel injects at the right time and the spark plugs ignite precisely, aligning with the engine’s cycle. A malfunction here and you might find your vehicle refusing to start.

Here’s a simple breakdown of the crankshaft sensor functions:

- Detects engine RPM

- Sends data to the engine control unit (ECU)

- ECU calculates optimal fuel injection timing

- Ensures accurate ignition timing

Link Between Crankshaft Sensor Failure And Starting Issues

The crankshaft sensor plays a pivotal role in your car’s ability to start. When it fails, the engine loses vital information needed to function. This sensor monitors the speed and position of the crankshaft, which is critical for the engine’s timing. If the sensor isn’t working, the car might not start. Let’s delve into how a faulty crankshaft sensor can specifically disrupt starting processes.

Loss Of Spark

An engine’s spark is crucial for starting. The crankshaft sensor sends signals to the ignition system. It tells the system when to ignite the air-fuel mixture. If the sensor fails, this process gets disrupted. The ignition system won’t know when to fire. As a result, the engine won’t start. This is why a non-functional crankshaft sensor can be a hidden culprit behind starting issues.

Fuel Injection Disruption

Your car’s fuel injection requires precise timing. The crankshaft sensor provides the timing marks. It ensures the correct amount of fuel enters the engine at the right time. If the sensor gives wrong signals, the engine receives an erratic fuel supply. This can cause the engine to stutter or not start at all. Sensor issues often mimic other problems, leading to misdiagnosis.

Summary of sensor issues:

- Essential for engine timing

- Signals when to ignite the mixture

- Failure leads to starting problems

- Affected fuel injection timing

Troubleshooting should start with a thorough check of sensor function. A diagnostic test can confirm crankshaft sensor issues. Replacing a faulty sensor often restores normal starting operations.

Credit: m.youtube.com

Diagnosing Crankshaft Sensor Problems

Diagnosing crankshaft sensor problems is crucial when a car refuses to start. A faulty crankshaft sensor can prevent your engine from running. It sends information about the engine’s speed and position to the car’s computer. Without this data, the engine may not ignite properly. Knowing how to check for issues can save time and money.

Error Codes And Check Engine Light

When a crankshaft sensor fails, the check engine light usually turns on. The car’s onboard diagnostics (OBD) system generates error codes. These codes help identify the issue.

- The OBD scanner connects to the car’s system.

- It reads the fault codes displayed.

- Common crankshaft sensor codes include P0335, P0336, etc.

Note the codes and research their meaning to understand the problem.

Diagnostic Testing Procedures

Follow these steps to confirm a crankshaft sensor problem:

- Connect an OBD scanner.

- Record any diagnostic trouble codes (DTCs).

- Perform a visual inspection of the sensor for damage.

- Use a multimeter to test the sensor’s resistance and voltage.

- Compare your results with the manufacturer’s specifications.

If the sensor tests fall outside standard ranges, replacement may be necessary. Timely diagnosis ensures your car stays reliable.

Fixing The Problem

When your car refuses to start, a faulty crankshaft sensor could be the culprit. The sensor’s role is critical in engine management. It ensures the engine’s timing is accurate. Without it, the vehicle might fail to ignite. Let’s dive into fixing this issue and getting you back on the road.

Steps For Replacing The Sensor

Replacing a crankshaft sensor is a task you might be able to do. Follow these steps to replace it:

- Locate the sensor: Check your vehicle manual. Every car has the sensor in a different place.

- Disconnect the battery: Ensure your safety. Always remove the negative cable first.

- Remove the old sensor: Unscrew any bolts holding the sensor. Gently pull it out.

- Compare sensors: Make sure your new sensor matches the old one.

- Install the new sensor: Place it where the old one sat. Secure it with bolts.

- Reconnect the battery: Attach the negative cable last after the positive one.

- Test your work: Start the car to check if the problem is fixed.

Ensuring Proper Timing And Connection

Correct timing and connection are vital for the sensor to work. Here’s how to ensure both:

- Check wiring: Inspect for any damaged wires or loose connections.

- Use diagnostic tools: They help you confirm the sensor is reporting correctly to the ECU.

- Follow manufacturer guidelines: Each vehicle has its setup. Stick to the manual for best results.

Take your time while working on these steps. Patience pays off in a smooth-running engine.

Credit: www.samarins.com

Preventive Measures And Regular Maintenance

Your vehicle relies on a symphony of components working in harmony.

A faulty crankshaft sensor can halt this harmony, preventing your car from starting.

To avoid such scenarios, engaging in preventive measures and regular maintenance is key.

Periodic Inspections

Consistent check-ups keep your car healthy.

Just as you would visit the doctor, your car needs regular inspections.

Scheduling periodic inspections with a professional is vital.

Maintain a calendar of routine inspections to ensure longevity and reliability.

| Inspection Area | Frequency |

|---|---|

| Crankshaft Sensor | Every oil change or every 5,000 miles |

| Electrical Connections | Annually |

Recognizing Early Signs Of Failure

Stay alert to subtle warnings that your crankshaft sensor may emit.

- Erratic starting issues

- Engine misfires

- Uneven acceleration

Catch these signs early, and you can prevent the inconvenience of a non-starting car.

Should any of these issues arise, seek immediate professional assistance.

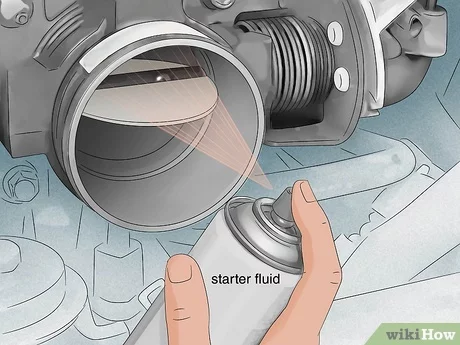

Credit: www.wikihow.com

Frequently Asked Questions Of Can A Crankshaft Sensor Cause A Car Not To Start

Can A Faulty Crankshaft Sensor Prevent Engine Start?

Yes, a faulty crankshaft sensor can prevent an engine from starting. The sensor provides crucial position and speed information to the engine control unit. If this data is missing or incorrect, the engine may not ignite the fuel-air mixture, leading to start failure.

How Does A Crankshaft Sensor Affect Car Performance?

A malfunctioning crankshaft sensor can lead to poor engine performance. Symptoms include uneven acceleration, engine misfires, and reduced fuel efficiency. It disrupts the engine timing, causing overall erratic behavior.

What Are Signs Of A Failing Crankshaft Sensor?

Signs of a failing crankshaft sensor include engine stalling, difficulty starting, and irregular engine performance. You might also observe a check engine light or experience reduced fuel economy. Prompt diagnosis is advised to avoid potential engine damage.

How Long Does A Crankshaft Sensor Last?

Typically, a crankshaft sensor should last the lifetime of the vehicle. However, it may need replacement after 100,000 miles or due to unexpected failure. It’s important to monitor for any signs of malfunction and address them early.

Conclusion

A faulty crankshaft sensor can indeed prevent your car from starting. It’s a pivotal component that affects engine functionality. Regular checks and early diagnostics are key. If you suspect a sensor issue, consulting a mechanic promptly could save you from a non-start scenario.

Drive safe and stay informed on car maintenance.