Can a Bad Crankshaft Sensor Cause a P0300 Code

A bad crankshaft sensor can indirectly lead to a P0300 code, which signifies a random misfire. The sensor’s malfunction might disrupt spark timing, contributing to engine misfires.

Understanding your vehicle’s diagnostic trouble codes (DTCs) is crucial for maintaining optimal performance and longevity. A P0300 code, a universal OBD-II code, can cause quite the headache for vehicle owners, signaling random or multiple misfires in the engine. Many factors can trigger this misfire, ranging from spark plug issues to fuel system problems.

Among these, a faulty crankshaft position sensor emerges as a potential culprit due to its role in managing engine timing and fuel injection. Although not the most obvious cause, a malfunctioning crankshaft sensor can create a cascade of engine issues, potentially leading to misfires reflected by the P0300 code. Regular maintenance and timely diagnostics are key in catching such issues early, ensuring your engine runs smoothly and reliably.

Credit: www.myautorepairadvice.com

Decoding The P0300 Trouble Code

When the dreaded check engine light illuminates, it’s like a cryptic puzzle waiting to be solved. Among the myriad of potential error codes, P0300 stands out. This code signals random or multiple misfires within your vehicle’s engine. But what could be the root cause? Could a faulty crankshaft sensor be the culprit? Let’s dive into the specifics of this particular trouble code.

The Basics Of Engine Misfire

An engine misfire occurs when the engine fails to ignite the fuel properly. This can lead to a lack of power, inefficient fuel economy, and an unsmooth ride. It’s like a symphony with a musician out of tune – the harmony is disturbed, and the performance is compromised.

Symptoms Associated With P0300

The P0300 code paints a picture of an engine in distress. Be on the lookout for these tell-tale signs:

- Check Engine Light: An obvious but vital indicator that something is amiss under the hood.

- Rough Idling: Does your car tremble or shake when at a stop? It could be a misfire.

- Reduced Gas Mileage: More frequent trips to the gas station could be a sign of inefficiency caused by misfires.

- Engine Hesitation: If acceleration feels like a challenge, it’s time to investigate further.

Understanding The Crankshaft Sensor’s Role

The crankshaft sensor plays a crucial part in your vehicle’s performance. It tracks the crankshaft’s position and speed, sending data to the car’s computer. This information ensures proper timing of fuel injection and ignition, keeping the engine running smoothly.

Function Of The Crankshaft Sensor

The function of the crankshaft sensor is key to engine management:

- Monitors crankshaft’s position and speed.

- Sends data for engine’s timing.

- Affects fuel injection and ignition timing.

- Helps prevent misfires, optimizing engine efficiency.

Signs Of A Failing Crankshaft Sensor

Be alert to these signs of a bad crankshaft sensor:

- Engine misfires or has irregular power.

- Hard starting or no start condition.

- Check engine light turns on.

- Poor acceleration, rough idle.

- Unexpected stalling.

Linking Crankshaft Sensor Failure To Engine Misfires

Imagine the heart of your car struggling to beat. That’s what happens when a crankshaft sensor fails. This tiny part plays a huge role in your car’s performance. When it fails, it might trigger a P0300 code. This code means your engine is misfiring. Let’s explore how a bad crankshaft sensor can cause this issue.

Effect On Ignition Timing

Ignition timing is crucial for smooth engine performance. The crankshaft sensor tells the engine when to ignite the fuel. If the sensor gives wrong information, the engine won’t know the right time to fire. This can cause the engine to misfire. Think of it like missing a step when you’re dancing.

Impact On Fuel Injection

The crankshaft sensor also controls fuel injection. With wrong sensor signals, your car might inject fuel at the wrong time. This mismatch can lead to fuel wastage and misfires. Your engine will cough and splutter like it has a cold.

Credit: www.reddit.com

Diagnostic Steps For Crankshaft Sensor Issues

The heart of your vehicle is its engine. A healthy engine relies on accurate information from the crankshaft sensor. When this sensor malfunctions, you may encounter a P0300 code. This code signals multiple misfires. Let’s dive into the diagnostic steps for crankshaft sensor issues that might lead to this problem.

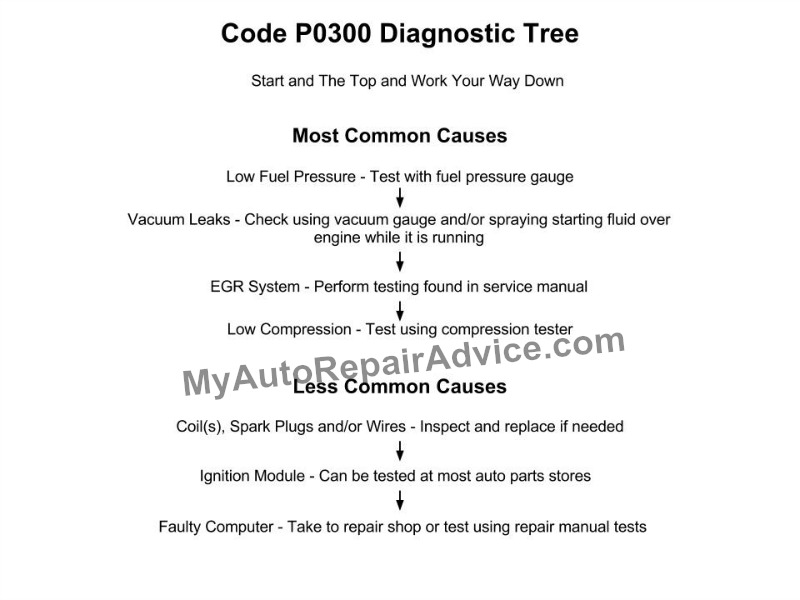

Troubleshooting The P0300 Code

Identifying the root cause of a P0300 code can be tricky. First, check the engine for common culprits:

- Faulty spark plugs or wires

- Issues with fuel delivery

- Ignition system defects

- Compression problems

After ruling out these issues, the focus turns to the crankshaft sensor. This sensor’s role is key in timing ignition and fuel injection.

Testing The Crankshaft Sensor

To test the crankshaft sensor, follow these steps:

- Connect a scan tool to read the engine codes and live data.

- Visually inspect the sensor and its wiring for damage.

- Use a multimeter to check the sensor’s resistance and voltage.

| Test | Expected Result |

|---|---|

| Resistance | Within specs |

| Voltage | Steady output |

If results are outside the normal range, replace the sensor. Remember, a defective crankshaft sensor can indeed mislead the engine’s control module and cause a P0300 code.

Addressing The Issue

Facing a P0300 code can be daunting. This infamous engine misfire code often leaves car owners concerned about their vehicle’s performance and longevity. The crankshaft position sensor plays a pivotal role in your engine’s operation. When it malfunctions, it may contribute to an array of issues, one being the P0300 code. Let’s delve into effective repair or replacement options and implement preventative measures to dodge future problems.

Repair Or Replacement Options

Acting swiftly on a P0300 code could save the engine from further harm. Here are tailored solutions:

- Diagnose – Verify the crankshaft sensor issue with proper diagnostic tools.

- Consult a Professional – Seek help from a certified mechanic for accurate solutions.

- Compare Costs – Evaluate the price difference between repair and replacement.

- Quality Parts – Choose OEM or equivalent quality sensors for a reliable fix.

Preventative Measures For Future

To prevent similar issues, proactive steps are crucial:

- Regular Checks – Schedule routine inspections of the crankshaft sensor.

- Maintain Vehicle Health – Follow the manufacturer’s recommended maintenance plan.

- Be Informed – Understand the signs of a failing sensor to act swiftly.

Credit: www.reddit.com

Frequently Asked Questions For Can A Bad Crankshaft Sensor Cause A P0300 Code

Can A Bad Crankshaft Sensor Trigger P0300 Code?

Yes, a faulty crankshaft position sensor can indirectly cause a P0300 code. This code indicates a random misfire, which can occur if the sensor fails to accurately monitor the engine’s speed and position, leading to improper ignition timing.

What Symptoms Accompany P0300 And Crankshaft Sensor Issues?

Symptoms can include rough idling, engine misfires, poor acceleration, stalling, and sometimes a ‘Check Engine’ light. If these occur together, it’s advisable to check both the crankshaft sensor and for misfires.

How Does A Crankshaft Sensor Work In An Engine?

A crankshaft sensor monitors the engine’s crankshaft speed and position. It sends signals to the engine control unit (ECU), which uses this data to control ignition timing and fuel injection, essential for engine performance.

Is It Costly To Replace A Crankshaft Position Sensor?

Replacing a crankshaft position sensor is generally not too costly. The part itself is reasonably priced, and labor costs are moderate since it is typically easily accessible for mechanics to replace.

Conclusion

A malfunctioning crankshaft sensor can indeed trigger a P0300 code. This diagnostic trouble code signifies random misfires, a situation the sensor can exacerbate. Regular vehicle diagnostics are essential to pinpoint this issue early. Remember to consult a professional mechanic for accurate assessments and timely repairs for optimal engine performance.