Can a Bad Knock Sensor Cause Stalling

A faulty knock sensor can indeed lead to engine stalling. It affects the timing and fuel-to-air ratio, critical for smooth engine operation.

A knock sensor plays a pivotal role in your vehicle’s performance; it detects vibrations indicating detonation or ‘knocking. ‘ The car’s computer relies on this information to adjust the timing of the ignition and the fuel mixture. Precise adjustments are crucial to prevent engine damage and ensure optimal performance.

If the sensor malfunctions, it can send incorrect signals to the engine control unit, leading to inefficient combustion, which may cause the engine to stall or run poorly. Detecting and addressing a bad knock sensor is essential in maintaining your vehicle’s health and preventing potential engine issues. A prompt replacement can save you from the inconvenience of unexpected stalling and further, more expensive repairs.

Credit: www.underhoodservice.com

The Role Of A Knock Sensor In Engine Performance

Knock sensors play a crucial role in maintaining the health and efficiency of a car’s engine. These sensory components detect vibrations that tell the story of the engine’s wellbeing. Without a properly functioning knock sensor, your vehicle may experience performance issues, including the frightening possibility of stalling.

Monitoring Engine Knock

Engine knock, also known as detonation, is a telltale symptom that an engine is operating under stress. It can be damaging over time, reducing both engine lifespan and performance. The knock sensor’s job is to monitor and detect this condition. Here’s how it works:

- Listen: The sensor listens for the irregular pings or knocks in the engine.

- Detect: Upon identifying these noises, it swiftly sends a signal to be analyzed.

Knock Sensor Feedback To The Ecu

Once the knock sensor senses engine knock, it reports back to the engine’s command center, the ECU (Engine Control Unit). This back-and-forth communication is pivotal for optimal engine function. Check out the process:

- The sensor detects the knock and generates an electrical signal.

- This signal is analyzed by the ECU, which interprets the severity and location of the knock.

- The ECU then adjusts the engine timing to immediately reduce the knock and protect the engine.

A faulty knock sensor means this vital feedback loop is broken. Consequently, the ECU remains uninformed about engine knock, which eventually could lead to stalling.

Symptoms Of A Faulty Knock Sensor

A vehicle’s knock sensor plays a vital role in engine performance and longevity. It detects vibrations indicating detonation, allowing the engine to adjust for optimal operation. A malfunctioning knock sensor can lead to various issues, potentially causing stalling and other problems. Understanding the symptoms of a faulty knock sensor can help identify issues early and avoid costly repairs.

Check Engine Light Activation

The check engine light is a telltale sign of many car troubles, including a bad knock sensor. When the sensor malfunctions, it sends incorrect data to the car’s computer system. This, in turn, triggers the check engine light. Drivers should not ignore this warning. A diagnostic check can confirm if the knock sensor is the culprit.

Poor Acceleration And Fuel Efficiency

Beyond the check engine light, a failing knock sensor impacts how a car drives. Symptoms often include:

- Poor Acceleration: The engine may hesitate or display sluggish response when you press the gas pedal.

- Fuel Efficiency Drops: You might notice that your car consumes more fuel than usual.

A faulty knock sensor can prevent the engine from adjusting its timing properly. This leads to inefficient combustion and, as a result, poor acceleration and increased fuel consumption.

| Issue | Symptom |

|---|---|

| Check Engine Light | Dashboard warning illuminates |

| Poor Acceleration | Hesitation or delay in response |

| Fuel Efficiency | Higher fuel consumption |

Drivers should pay attention to these signs and act promptly. Early diagnosis can prevent further engine damage, saving time and money. Regular maintenance checks help ensure the knock sensor and other key engine components function correctly.

Consequences Of Ignoring A Bad Knock Sensor

A knock sensor plays a critical role in your vehicle’s engine function. It listens for pre-detonation or “knocking” sounds that can damage the engine. Ignoring a faulty knock sensor can lead to a cascade of engine issues. Let’s explore what might happen if this component doesn’t get the attention it needs.

Potential Engine Damage

The knock sensor detects irregular vibrations and sounds, signaling the engine to adjust the timing. Without these crucial corrections, your engine can suffer:

- Increased Stress: Unchecked pre-detonation causes added stress on engine components.

- Piston Damage: The high pressure from knocking can lead to cracks or holes in pistons.

- Head Gasket Failure: Prolonged knocking might breach the seal, causing leaks.

- Bearing Wear: Intense forces can wear down bearings prematurely.

These engine damages are costly repairs that can be prevented by addressing a bad knock sensor early on.

Reduced Driveability

Ignoring signs of a bad knock sensor can affect how your car drives. Notice these reduced driveability symptoms:

| Driveability Issue | Result of Ignored Knock Sensor |

|---|---|

| Stalling: | Improper fuel mixture makes the engine stall. |

| Poor Acceleration: | Lack of proper spark timing leads to sluggish response. |

| Irregular Idling: | Engine timing issues cause rough or fluctuating idle speeds. |

| Decreased Fuel Efficiency: | Engine knock can cause more fuel to be consumed than necessary. |

Addressing a failing knock sensor swiftly can ensure smooth drives and conserve fuel, saving money and inconvenience.

Troubleshooting Knock Sensor Issues

A vehicle’s knock sensor plays a crucial role in engine performance. Identifying knock sensor issues is key to preventing stalling and maintaining smooth operation. This section guides through diagnostics and professional testing methods.

Diagnostic Trouble Codes (dtcs)

Diagnostic Trouble Codes can reveal knock sensor problems. Use an OBD-II scanner to read these codes:

- P0325 – Knock Sensor Circuit Malfunction

- P0330 – Knock Sensor 2 Circuit Malfunction (Bank 2)

- Codes starting with P0331 to P0334 indicate issues with the sensor’s performance or circuit.

If such codes appear, further investigation is needed to confirm the sensor’s status.

Professional Knock Sensor Testing

A thorough knock sensor test is best done by professionals. They perform steps that include:

- Checking the electrical connection.

- Testing sensor resistance with a multimeter.

- Assessing the sensor’s voltage response to vibration.

Affected vehicles manifest symptoms such as poor acceleration, increased fuel consumption, and engine noise. Immediate attention can prevent stalling.

Can A Faulty Knock Sensor Lead To Stalling?

Can a Faulty Knock Sensor Lead to Stalling?

Detecting engine knock is vital. A faulty knock sensor might sound like a minor glitch. Yet, it can severely disrupt an engine’s performance. But could it cause your car to stall? Let’s explore the connection and what experts say about this pesky problem.

The Link Between Knock Sensors And Engine Stalling

Knock sensors maintain engine rhythm by detecting abnormal vibrations, also known as ‘knock’. A bad sensor may send incorrect signals. This can confuse the engine’s computer, which adjusts the timing and fuel mix.

When the mix goes awry, the engine can stall. This is because it’s not burning fuel as it should. Imagine a professional dancer suddenly forgetting the steps – that’s your engine without proper knock sensor input.

- Wrong timing: Leads to inefficient fuel burning

- Poor fuel mix: Results in incomplete combustion

- Engine stalling: Occurs when combustion fails

Case Studies And Expert Opinions

Experts analyze real scenarios to understand issues. Verified cases shed light on stalling caused by bad knock sensors. Certified mechanics report on engines fixed after replacing faulty sensors.

| Car Model | Stalling Issue | Solution |

|---|---|---|

| Model X | Intermittent Stalling | Knock Sensor Replaced |

| Model Y | Stall at Idle | Kncok Sensor Replaced |

Mechanics agree: faulty knock sensors can cause stalling. They stress timely repairs to prevent engine damage. Your car relies on accurate data to run smoothly – ensure it gets it.

Credit: qcwo.com

Fixing A Bad Knock Sensor

A faulty knock sensor may lead to engine stalling. Fixing a bad knock sensor is crucial for the smooth operation of your vehicle. It aids in preventing damage from engine knock or pinging. Let’s inspect how to tackle this issue, from replacement to the importance of OEM parts.

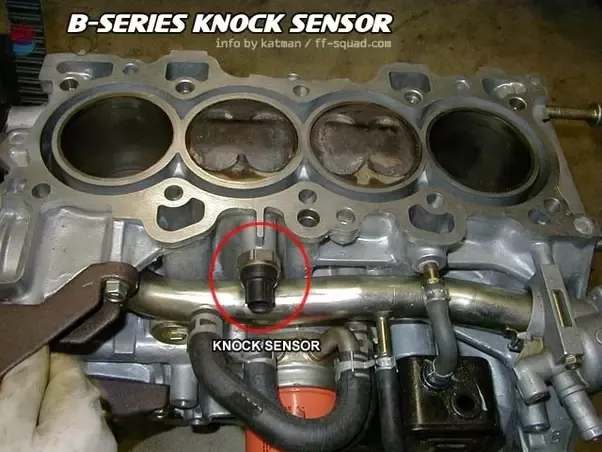

Replacement Process

Replacing a knock sensor involves several steps:

- Locate the sensor – Found on the engine block.

- Disconnect the battery – Safety first.

- Remove the sensor – Unbolt carefully.

- Install the new sensor – Secure it in place.

- Reconnect the battery – Test the engine.

Tools like a socket set and wrench are necessary. Make sure to follow the specific service manual for your car model.

The Importance Of Oem Parts

OEM parts mean ‘Original Equipment Manufacturer’ parts. They match the parts your car was built with. Here’s why they matter:

- Perfect fit – Made for your car model.

- Quality assurance – Tested by the manufacturer.

- Warranty coverage – Often supported by a warranty.

Choosing OEM knock sensors ensures compatibility and reliability. Although they might come at a higher price, they offer peace of mind.

Preventative Measures To Avoid Knock Sensor Problems

Preventative measures matter greatly for maintaining the health of a vehicle’s knock sensor. This little component can have a big impact on your car’s performance, often leading to unwanted stalling if neglected. To prevent this, let’s dive into some practical steps you can take to avoid knock sensor problems.

Regular Vehicle Maintenance

Keeping up with scheduled vehicle check-ups is essential. Mechanics can spot early signs of wear and tear. This includes a knock sensor check. They ensure it functions properly and has not succumbed to engine vibrations or heat damage. Remember, early detection saves money and stress.

- Check engine codes regularly with an OBD-II scanner.

- Inspect wiring for corrosion or disconnections.

- Listen for unusual noises that may indicate a faulty sensor.

- Ensure timely replacement of worn out parts.

Using The Right Fuel Type

Always refuel with the correct grade of gasoline. Your vehicle manual specifies the right type. Using lower-octane fuel than recommended can cause the engine to knock. This puts stress on the knock sensor. Over time, it may fail, possibly leading to stalling and other engine issues.

| Fuel Type | Benefits | Risks of Wrong Choice |

|---|---|---|

| High Octane | Optimizes performance | Can be costly, but necessary for some engines |

| Regular Unleaded | Cost-effective for many cars | Possible knocking in high-compression engines |

By adhering to these simple preventative steps, the likelihood of your knock sensor causing stalling is reduced. Regular maintenance and correct fuel usage maintain engine health and sensor integrity. Keep your engine happy, and drive assured, knowing you’ve taken proactive measures to keep your knock sensor in check.

Credit: www.justanswer.com

Frequently Asked Questions For Can A Bad Knock Sensor Cause Stalling

Can A Failed Knock Sensor Lead To Engine Stalling?

Yes, a faulty knock sensor can cause an engine to stall. The sensor’s role is to detect engine knocking and signal the computer to adjust the ignition timing. If it fails, this process is disrupted, potentially leading to stalling, poor acceleration, and a decrease in fuel efficiency.

What Symptoms Indicate A Knock Sensor Issue?

Common symptoms of a knock sensor problem include the check engine light turning on, reduced engine performance, unusual noises from the engine, and in some cases, engine stalling. Diagnosis via an OBD-II scanner can confirm the issue.

How Does A Knock Sensor Affect Engine Performance?

A knock sensor affects engine performance by monitoring engine knocking and prompting timing adjustments. A malfunctioning sensor may fail to regulate the timing properly, causing misfires, reduced power, and possible engine damage if left unchecked.

Is Replacing A Knock Sensor A Costly Repair?

The cost of replacing a knock sensor varies by vehicle make and model but typically ranges from modest to moderately expensive. The part itself is not usually overly costly, but labor charges can add up depending on the sensor’s location and accessibility.

Conclusion

Troubles with your knock sensor can indeed lead to stalling. Considering the sensor’s role in engine management, its failure disrupts vital operations. Regular maintenance checks help spot early signs of malfunction. Address sensor issues swiftly to maintain your vehicle’s performance and safety.

Remember, a healthy engine relies on accurate sensor feedback.