How to Check Trailer Wheel Bearings

To check trailer wheel bearings, jack up the trailer, spin the wheel and listen for noise, and wiggle the tire for play. For a thorough inspection, remove the wheel and check for smooth rotation and signs of wear or damage.

Checking your trailer wheel bearings regularly can ensure that your trailer remains safe and reliable on the road. Misconceptions abound when it comes to maintenance, but understanding how to properly assess your trailer’s wheel bearings doesn’t need to be complicated.

With the correct tools and a bit of knowledge, you can diagnose potential issues before they escalate into costly repairs. Proper maintenance not only extends the life of your trailer but also promotes safety by preventing wheel failure. This guide will provide you with the step-by-step process to accurately assess the condition of your trailer’s wheel bearings, helping you to keep your travels smooth and uninterrupted. Stay vigilant about your trailer’s upkeep to enjoy a hitch-free journey wherever you go.

Credit: www.boatus.com

Significance Of Maintaining Trailer Wheel Bearings

Keeping trailer wheel bearings in top condition is crucial for the smooth running of your trailer. Like a hidden hero behind the wheels, they enable effortless rotation with minimal friction. Regular checks ensure your trailer’s reliability, longevity, and safety on the road.

The Role of Wheel Bearings in Trailer SafetyThe Role Of Wheel Bearings In Trailer Safety

Wheel bearings play a vital role in trailer safety. They are responsible for:

- Stable towing by reducing friction during wheel rotation

- Maintaining wheel alignment and balance

- Minimizing wear and extending tire life

Bearings in good condition can mean the difference between a smooth ride and a potential roadside emergency.

Consequences of Neglecting Bearing MaintenanceConsequences Of Neglecting Bearing Maintenance

Ignoring bearing maintenance can lead to:

- Increase in friction and heat, causing severe damage

- Potential wheel lockups or detachments

- Costly repairs and replacements down the line

Regular inspections and maintenance of bearings prevent these risks, ensuring a safe and enjoyable journey.

Preliminary Steps Before Inspection

Keeping trailer wheel bearings in top condition is crucial for safety on the road. Regular checks prevent breakdowns and maintain performance. The preliminary steps before inspection set the stage for a thorough and safe maintenance activity. Let’s prepare properly.

Gathering The Necessary Tools

Start by assembling the right tools:

- Jack and jack stands to lift and secure the trailer.

- Wheel chocks to prevent rolling.

- Wrench set to remove lug nuts.

- Flat-head screwdriver or pry bar to remove caps.

- Clean rags for wiping grease.

- Pliers to remove cotter pins.

Safety Measures And Preparations

Follow these safety steps:

- Find a flat, stable surface for your trailer.

- Use wheel chocks on both sides of the opposite tire.

- Be sure to jack the trailer securely.

- Place jack stands under the frame or axle.

- Remove the wheel, exposing the hub with caution.

Visual Inspection Guide

Regular checks on trailer wheel bearings prevent breakdowns during trips. This guide helps spot issues early. Let’s learn how to visually inspect these components closely.

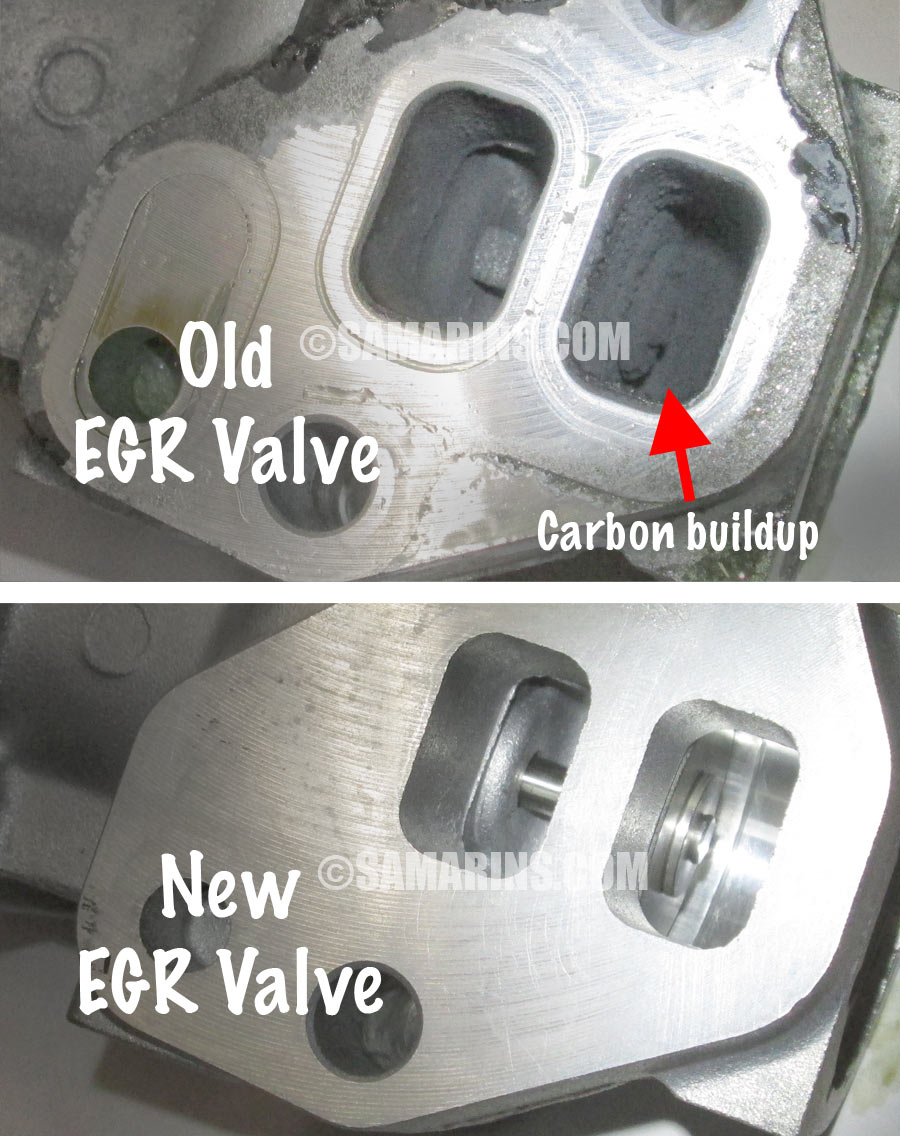

Identifying Signs Of Wear And Tear

Look for these signs:

- Discoloration: Bearings may turn blue or brown from overheating.

- Scoring: Grooves inside the race signal distress.

- Corrosion: Rust indicates moisture damage.

- Brinelling: Dents in the race from heavy impact.

- Seal damage: Broken seals let in dirt and debris.

Understanding Abnormal Noises And Movements

Pay attention to these:

| Noise/Movement | Potential Issue |

|---|---|

| Grinding: | Metal against metal, lack of lubrication. |

| Popping: | Detached or broken rollers inside the bearing. |

| Humming: | Irregularities in the bearing surfaces. |

| Wobble: | Loose fit or worn out bearings. |

Credit: www.boatus.com

Hands-on Inspection Procedures

When it comes to trailer maintenance, wheel bearings play a pivotal role. Regular inspection prevents breakdowns. Let’s dive into hands-on inspection procedures for checking the health of your trailer wheel bearings.

Jacking Up The Trailer Safely

Safety comes first. Follow these steps to lift your trailer securely:

- Find a flat, stable surface to work on.

- Place wheel chocks around the wheels that will remain on the ground.

- Locate your trailer’s jacking point. It’s often found in the owner’s manual.

- Use a sturdy jack that can support your trailer’s weight.

- Gently lift until the wheel is off the ground.

Checking For Play And Smoothness In The Bearings

Next, examine the bearings for any signs of wear and tear:

- Grasp the wheel at the top and bottom and rock it back and forth.

- Note any excessive movement, which suggests worn bearings.

- Rotate the wheel slowly. It should turn freely and smoothly.

- Roughness or grinding noises indicate that bearings need attention.

Consistent care ensures your trailer is ready for the road. Check bearings regularly to stay safe on your travels.

Advanced Maintenance Techniques

Maintaining your trailer involves more than just a quick glance at the wheels. Advanced techniques ensure your safety and extend the lifespan of your trailer. Regular care, such as lubricating and replacing wheel bearings, are vital to your trailer’s performance.

Lubricating The Bearings

Proper lubrication is crucial for the health of your trailer’s wheel bearings. Here’s a step-by-step process:

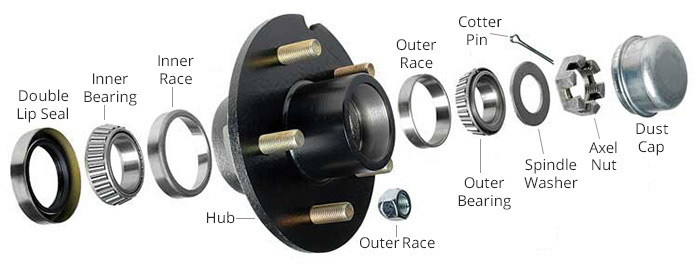

- Remove the hubcap or bearing cover.

- Take off the cotter pin and retaining ring.

- Extract the bearing and clean it thoroughly with solvent.

- Inspect the bearing for wear or damage.

- Apply high-quality, grease to the bearing.

- Rotate the bearing while adding grease to ensure full coverage.

- Reassemble the components and ensure there’s no excess grease that could attract dirt.

Replacing Worn-out Bearings

Replacing worn-out bearings is key to safe travels. Follow these steps:

- Detect damage by checking for irregularities or roughness as the wheel turns.

- Loosen the lug nuts and lift the trailer using a jack.

- Remove the tire to expose the hub.

- Take out the old bearings and clean the seating area.

- Compare new bearings with old to confirm the correct size.

- Install new bearings and secure them in place.

- Grease the new bearings and rotate to ensure smooth movement.

- Replace the hub assembly and tire, and tighten the lug nuts securely.

Always use precise tools and follow the manufacturer’s specifications. Remember to wear safety gear while performing these advanced maintenance tasks.

Credit: m.youtube.com

Post-inspection Practices

Once you’ve carefully inspected your trailer’s wheel bearings, it’s time to put everything back together. Proper reassembly and maintenance records are crucial. These steps ensure safety and longevity for your trailer’s wheels. Let’s dive into the proper post-inspection practices.

Reassembling The Wheel Assembly

Reassembling the wheel assembly is simple if you follow these steps:

- Return the bearings: Place the clean, inspected bearings back in the hub.

- Seal the hub: Put a new seal on the hub to protect the bearings from dirt and moisture.

- Attach the hub: Mount the hub back onto the axle.

- Tighten the nut: Adjust the castle nut to the correct torque for your specific trailer model.

- Secure with a pin: Place a new cotter pin to lock the nut in place.

- Reattach the wheel: Put the wheel back on and bolt it firmly.

Now that everything’s back in place, your trailer’s ready for the road!

Recording Maintenance For Future Reference

Keep a detailed record of the maintenance:

| Date | Service Performed | Technician Name |

|---|---|---|

| MM/DD/YYYY | Wheel Bearing Inspection | John Doe |

Document all services, including dates, actions taken, and technician info. Keep this log with your trailer or in a digital format for easy access. This log is useful for future inspections and when assessing any potential warranty claims.

Frequently Asked Questions Of How To Check Trailer Wheel Bearings

How To Tell If Trailer Bearings Need Replacement?

To identify if trailer bearings require replacement, check for unusual noises, wheel wobble, or excessive heat around the wheel hub. Regular inspection and maintenance can prevent potential bearing failure.

What Tools Are Needed To Check Trailer Wheel Bearings?

Essential tools for checking trailer wheel bearings include a jack to lift the trailer, pliers or a wrench to remove the hubcap, and a torque wrench. Adequate safety gear such as gloves and safety glasses is also recommended.

What Are The Steps To Inspect Trailer Wheel Bearings?

Begin by lifting the trailer and securing it on jack stands. After removing the wheel and hubcap, spin the hub and listen for grinding noises. Check for play or wobble in the wheel, which indicates wear.

Can You Grease Trailer Wheel Bearings Without Removing Them?

It’s possible to grease trailer wheel bearings without full removal using a grease gun and compatible grease fitting. Ensure the grease is compatible with the bearings and avoid overfilling to prevent leakage.

Conclusion

Regular inspection and maintenance of your trailer’s wheel bearings are crucial for safe towing. Mastering this skill ensures longevity for your trailer and peace of mind on your journeys. Remember, the key is to be proactive in checking for wear and tear.

Safe travels and happy towing!