Why are Car Repairs Taking So Long

Car repairs are taking longer due to parts shortages and increased demand. Skilled labor scarcity also contributes to delays.

Navigating the current automotive landscape can be frustrating, especially when it comes to car repairs. A perfect storm of supply chain disruptions has led to a pressing scarcity of auto parts. This challenge is compounded by the dramatic surge in demand for vehicle servicing as more people hold onto their cars longer.

The industry is also grappling with a shortage of skilled mechanics, which complicates scheduling and extends wait times. Owners, feeling the squeeze, are often left with lengthier downtimes for their vehicles. These factors converge to create a scenario where patience is not just a virtue, but a necessity for car owners seeking repairs. It’s essential to understand and anticipate these disruptions when planning for vehicle maintenance.

Rise In Vehicle Complexity

The rise in vehicle complexity is an undeniable trend in the automotive world. Today’s cars are no longer just machines with wheels and engines. Instead, they have become high-tech devices on the move. With the sophistication of modern vehicles comes a set of challenges, especially when they need repairs.

Shift To Advanced Electronic Systems

Recent years have ushered in a leap from mechanical to electronic platforms in cars. The once simple systems are now networks of intricate electronic components:

- Touchscreen interfaces

- Automated safety features

- Energy-efficient powertrains

Mechanics must now become versed in complex electronic systems. This requires extra time for training and diagnostics.

Integration Of Software With Hardware

Modern vehicles integrate software and hardware in ways never seen before. These elements work together to control various vehicle functions. For example:

| Function | Hardware | Software |

|---|---|---|

| Navigation | GPS Unit | Mapping Software |

| Engine Management | Sensors | Control Algorithms |

Repairing these systems often requires software updates or hardware replacements. This combination can significantly extend repair times.

Credit: www.quora.com

Supply Chain Disruptions

Vehicles fill our streets, but repair bays are silent. You might ask, “Why are car repairs taking ages?.” Peek under the hood of the global auto industry, and you’ll spot gremlins in the gears – supply chain disruptions. This unseen mess spares no one, leaving drivers and mechanics alike in a lurch. Let’s explore how tangled supply lines put a stick in the spokes of prompt repair work.

Global Parts Shortage

A web of reliance links car parts across continents. When one node wobbles, the entire web vibrates. Delays crop up like dominos, from raw materials to shiny car components. Here’s how this affects repairs:

- Soaring wait times for basic components

- Increased repair costs as part prices skyrocket

- Customer frustration mounts, mechanics’ hands are tied

Impact Of Pandemics And Natural Disasters

Nature’s fury and global health scares throw wrenches into the works. Work stops, factories shut down, and shipments drift in limbo. This leads to:

- Important parts trapped overseas or at sea

- Local suppliers struggle to fill the void

- Maintenance schedules stretch thin, and tempers fray

| Issue | Consequence in Repairs |

|---|---|

| Shortage of Microchips | Modern cars idle waiting for brains |

| Logistics Slowdown | Parts’ journeys lengthen, delaying fixes |

| Rubber Shortage | Tires hard to come by, replacements delayed |

In summary, supply chain woes bog down car repairs. A mixture of shortages and disasters create a tricky road for drivers seeking quick fixes. Understanding these knots helps foster patience, as we all await the industry’s return to nimble repairs.

Skilled Labor Shortage

The wait times for car repairs are stretching longer than ever. One significant roadblock facing the auto repair industry is the skilled labor shortage. Today, finding a qualified technician is like looking for a needle in a haystack. This shortage echoes through every auto repair shop, from local garages to dealership service centers.

Decline In Qualified Technicians

Many factors contribute to the declining numbers of skilled car mechanics. Older, experienced mechanics are retiring. Young people often choose different career paths. Shops across the nation are feeling the pinch. Without enough hands on deck, repair times take a hit. Each car sits longer, and customer frustrations grow.

- Retirements outpace new entrants into the field.

- Lack of interest among younger generations in pursuing automotive careers.

- Shops struggle to fill vacant positions with qualified candidates.

Need For Specialized Training

Cars today are complex machines, filled with advanced electronics and systems. Fixing a modern vehicle often requires specialized knowledge. This need for specialized training is a stumbling block. Many current mechanics lack the necessary skills. The result? Repairs that are delayed or incomplete.

Becoming proficient in modern car systems involves:

- Extensive technical education.

- Continuous learning to keep up with evolving technology.

- Access to specialized tools and diagnostic equipment.

To curb the shortage, the industry must invest in training. Prospective technicians need incentives to join and stay in the profession. Ultimately, this investment will lead to faster, more efficient repairs.

Increase In Diagnostic Time

The ‘Increase in Diagnostic Time’ seems to be a thorn in the side of many vehicle owners. As cars evolve into complex machines, pinpointing problems is not as straightforward as it once was. Understanding this aspect of car repair is key to managing expectations and planning for vehicle maintenance schedules.

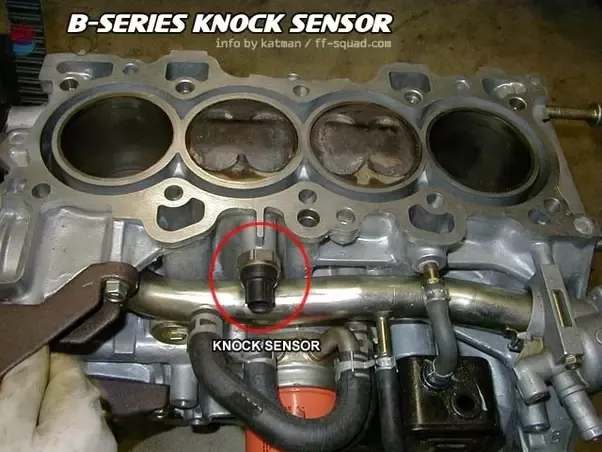

Advanced Tools For Troubleshooting

Modern vehicles are now equipped with sophisticated systems that require advanced tools for effective diagnosis. Unlike the simple toolsets of the past, today’s diagnostics demand more than a mere visual check.

- Onboard computers oversee vital car functions, requiring specific software to read their codes.

- Technicians use specialized scanners to interface with these computers.

- Updates and calibrations for these advanced tools also add time to the diagnostic process.

Thorough Analysis For Precision Repairs

Accuracy in identifying automotive problems prevents unnecessary repairs, saving time and money in the long run. Comprehensive analysis ensures that every repair is just as precise as the diagnosis itself.

- Mechanics must perform a series of tests to rule out possible issues.

- Diagnostic procedures can be extensive, involving the checking of multiple systems.

- The aim is to guarantee that the root cause is addressed, not just the symptoms.

Diligence in the diagnostic phase reflects a commitment to quality and vehicle longevity, although it requires patience from car owners.

Quality Control Standards

Imagine waiting longer for your car repair, and you might feel frustrated. Quality control standards are behind these delays. These standards ensure your car is safe and reliable. This means more checks and tests. Your car gets the best care, even if it takes a bit longer.

Ensuring Safety And Reliability

Car shops follow strict rules to keep you safe. They must check every part of your car. They look for tiny problems that could be big dangers later. This process is thorough. It’s like a doctor checking you from head to toe.

- Brake systems undergo intense inspections

- Engine parts are tested for peak performance

- Tire wear is measured to keep trips smooth

Extended Verification Procedures

Every repair job goes through many tests. These tests check that repairs meet high standards. Mechanics take time to ensure everything works perfectly.

| Check | Description |

|---|---|

| Diagnostic Tests | Electronic tools find hidden car problems |

| Road Tests | Driving the car to ensure repairs are effective |

| Quality Review | A final look-over by a senior mechanic |

These steps make sure your car is as good as new. Patience brings the reward of a car that won’t let you down. Next time you’re waiting for your car, remember that good things take time!

Credit: www.northernnewsnow.com

Frequently Asked Questions On Why Are Car Repairs Taking So Long

Why Is There A Delay In Car Repair Services?

Car repair delays often stem from parts shortages, mechanic availability, or workshop backlogs. These issues can extend repair times considerably, leading to inconvenient wait periods for vehicle owners.

What Causes Auto Parts Supply Shortages?

Supply shortages for auto parts are usually due to manufacturing delays, transportation bottlenecks, or increased demand. Global events, like pandemics or trade disputes, can exacerbate these issues, affecting the supply chain.

Can Skilled Mechanic Shortages Affect Repair Times?

Yes, a lack of skilled mechanics can significantly increase repair times. Workshops may struggle to keep up with demand, resulting in longer waiting periods for car repairs.

How Do Workshop Backlogs Impact Car Repair Duration?

Workshop backlogs occur when there’s a high volume of repair orders. This leads to a queue, causing each subsequent repair to take longer as mechanics work through the backlog.

Conclusion

Navigating the complexities of auto repairs requires patience and understanding. Delays often stem from parts shortages, busy shops, and intricate technology. By planning ahead and communicating with your mechanic, you can minimize the inconvenience. Remember, quality repairs are worth the wait for a safe and reliable vehicle.